Don’t waste valuable heat

Any company that chills and freezes products on an industrial scale generates a large amount of waste heat. This is because the refrigeration and freezing equipment extracts heat from the refrigerated and frozen products and dissipates it outside. Although this is enough to heat a block of flats, it is usually lost to the outside air or washed away with waste water. Tens of thousands of euros are often wasted in this way.

Don’t want to waste valuable heat? With our heat recovery technology, you can capture residual heat from the cooling and freezing process and use it in other processes. This prevents energy waste. Is the temperature of the heat too low? With an industrial heat pump and, if necessary, other technological solutions, you can sustainably raise it to 80 to 90°C and above. This generates so much heat from residual heat that you can make significant savings on heating costs. In addition, you can also heat without using gas.

Reduce energy consumption? Use residual heat to meet your heating needs.

Request a free information brochureHeat recovery in industry

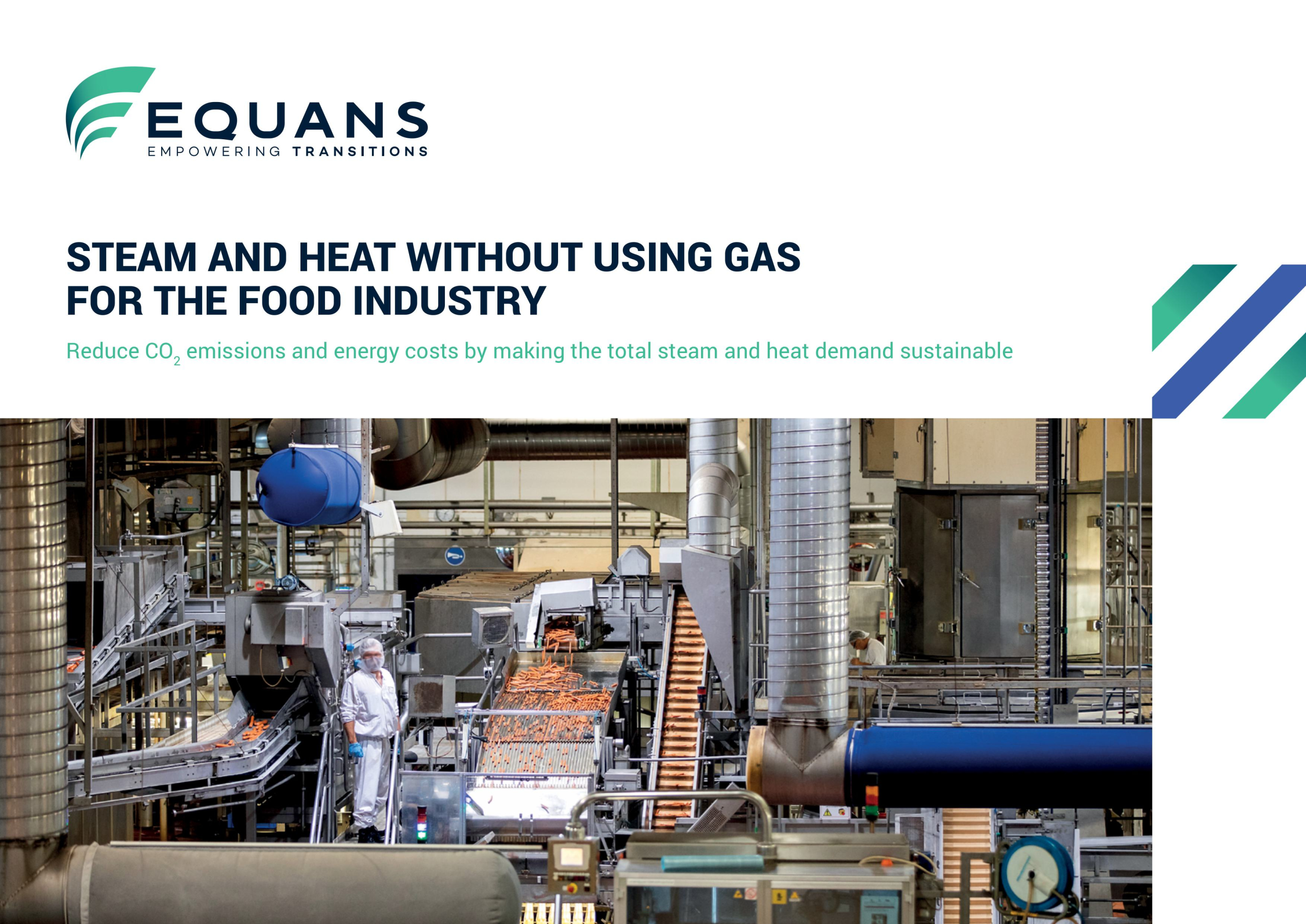

Are you active in food processing or the potato and onion industry? Then industrial heat recovery is of particular interest to your business. That’s because both cooling and heating are needed simultaneously. Equans anticipates this with tailor-made solutions. While the refrigeration and freezing units do its job, a heat recovery system allows you to use the recovered residual heat for other processes in the company. This saves electricity and gas.

Heat recovery applications

Are you still heating water for cleaning processes, for example, with a gas boiler? Rising gas prices and uncertain gas availability are not doing your business any favours. By investing in heat recovery technology and possibly a heat pump for water heating, you will not only have a better carbon footprint and a more sustainable production process, but you will also safeguard future operations and continuity of production. After all, electricity, sustainable or not, is always available.

Captured residual heat can be used, for example, for

- Sterilising

- Pasteurisation

- Blanching

- Temperering

- Drying

- Cleaning

- Heating of (office) spaces

- Heating of process water

Wondering how our heat recovery technology works in practice every day? Then read the Grozette case study. For this customer, we built a drying tunnel with an integrated cooling and heating installation. This enables the cheesemaker to dry cheese products without using gas. The result is an energy saving of more than 40%.

Storing residual heat

If you do not immediately need the residual heat, then it’s a option to store the residual heat, for example, in a heat buffer. In this case, we convert the residual heat into hot water, which can later be used to heat office spaces, for instance. This way, we use all possibilities in a smart way.

Saving energy with heat recovery

Industrial heat recovery makes the most of existing heat and energy flows. The logical consequence is significantly lower energy costs and CO2 emissions. By reusing residual heat, you can eliminate the need for gas-fired heating and save tens of thousands of kilowatt hours per year.

Need steam and heat for your production process? Check out our gas-free solutions. Reduce your CO2 emissions and energy costs!

Request a free information brochureIndustrial heat recovery payback period

Are you looking to make smarter use of heat and energy flows through heat recovery? We can provide a no-obligation calculation of the energy savings that can be made by reusing waste heat in your business. We look at the whole business process: the processes that use and give off heat, the hot water consumption and the different temperature levels in the company.

Within a few days you will receive the business case with the payback period so you can make an informed decision. And did you know that there are attractive tax incentives for using industrial heat recovery? For example, the Energy Investment Allowance (EIA) allows you to deduct 45.5% of the investment costs from your profits (2022). This allows a payback period of less than 3 years.