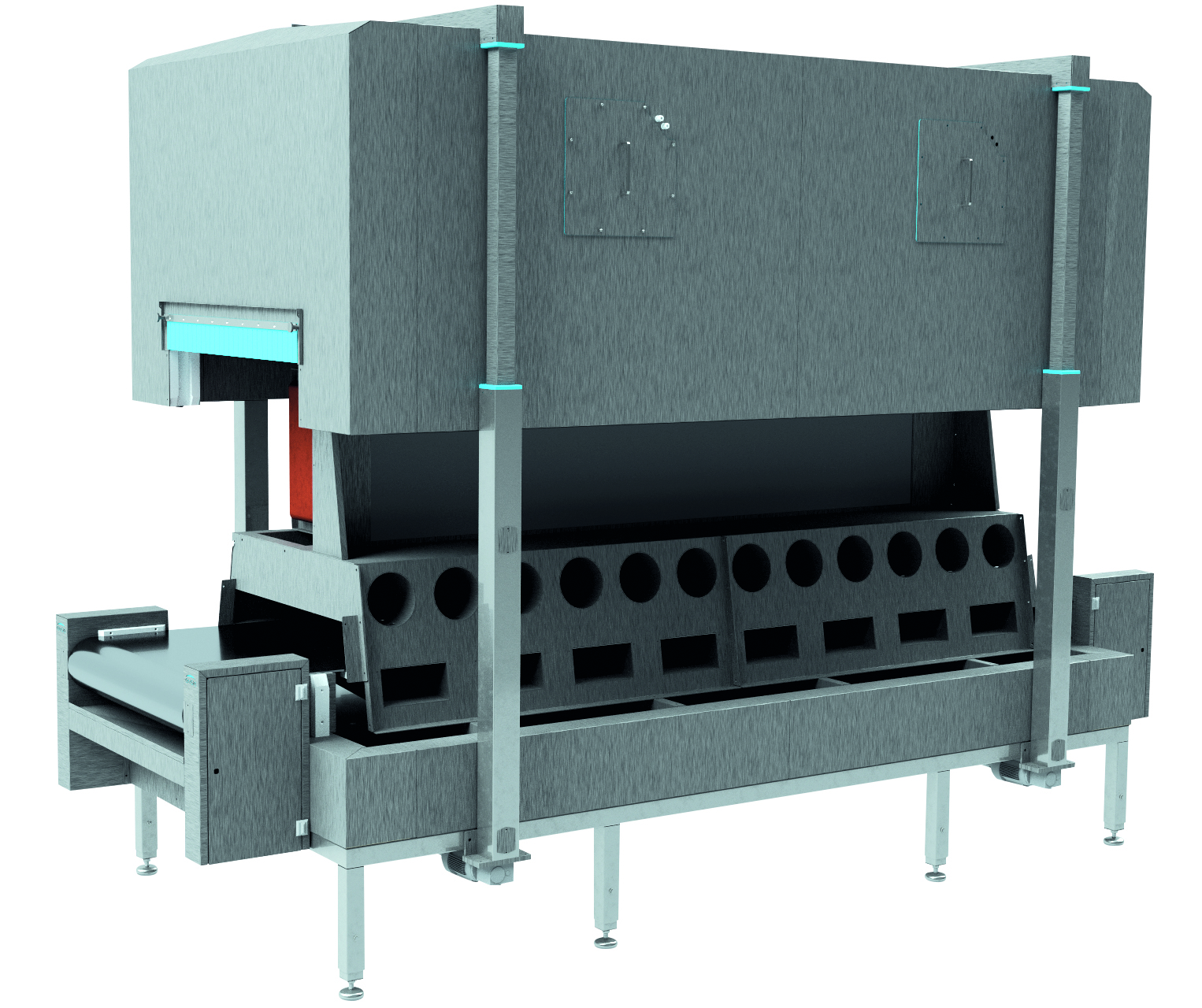

Customised to you products and processes

Better product freezing results in higher yields and prices. There are several factors which determine perfect freezing. Think about the type of product, its thickness and its packaging. Because the characteristics of each product is known for perfect freezing, we can design a freezer that is completely tailored to the product and the way you process it. We call this intelligent IQF freezing. We test the installation beforehand, both in our laboratory and on your premises. As a result, our freezing technology delivers the end product you want.

Preserving quality while freezing

Ultra-fast freezing and post-freezing (glazing) is better for the cell structure of your fish, meat or vegetables than conventional deep-freeze technology. Fluids and important nutrients are retained in the product and because it dries out less, not only the quality but also the volume of your product is retained. This has a positive effect on your yield.

Freezing products ultra-fast and maintaining quality? Go for IQF freezing.

Request a free information brochureService life and efficiency improvement

With our smart freezing technology, freezing is so fast that less moisture is released than with a conventional system. As a result, the freezer has fewer problems with ice growth, which doubles the service life and significantly increases your productivity. Thanks to the smart design you can clean the installations quickly and easily. Therefore, our technology is always awarded the highest scores during HACCP inspections. The start-up time is also twice as fast as for a conventional freezer.

Exclude cryogenic gases

Thicker foods such as meatballs and sausage rolls require high freezing intensity. They are often frozen using cryogenic gases at a temperature of -80°C. This results in high operating costs and high gas consumption. With our freezing technology you can achieve equivalent freezing results without using cryogenic gases. This results in much lower operating costs.

Want to secure your business operations? Take advantage of the opportunities of phasing out synthetic refrigerants.

Request a free information brochure

Sustainable freezing and energy savings

Ultra-fast freezing with IQF technology uses significantly less energy without compromising performance. You can save up to 20% on energy and because our freezing systems use natural refrigerants, you contribute to a sustainable food chain and ensure the continuity of your business.

Opportunities for heat recovery

When freezing fresh or convenience products, a fast and cold airflow is important. By blowing as much cold air as possible past the product, the heat from the product is removed quickly. With an add-on heat pump, you can collect the heat and increase the temperature for use in other processes where heat is required. You can also reuse the residual heat from the cooling system. Equans offers technology that captures heat, stores it and make it available at a later stage to other process.

Reduce energy consumption? Use residual heat to meet your heating needs.

Request a free information brochureOptimising the freezing process

As a food processor, you can make a lot of money by optimising the freezing process. When designing the freezing process, the cooling system, freezing lines and peripherals are often designed and installed separately, even though these parts are closely related. With our integrated freezing technology, the cooling system, freezing lines and peripherals are precisely coordinated with an intelligent control system.

Customised or standard equipment

We design and manufacture compact freezing systems, incorporating all the latest technologies. By fine-tuning them, our freezing technology seamlessly meets all your requirements and needs. You also receive the optimum balance between quality, efficiency and energy consumption. If a standard size freezer does not fit, we can offer you a custom-made one.

A compact setup

We optimise your available space through clever design and combination. Because of standard modules, each unit can be designed in different dimensions and easily combined with other units. Unit components remain interchangeable, so you benefit from continuity and ease of maintenance.

Wondering how our freezing technology works in practice every day? Then read the case study of Gebr. Kramer. We replaced the entire freezing installation for this customer. The fish processor now has more capacity and better product quality. It also uses less water and energy, resulting in significant savings.

Integrated operating system

Our IT specialists develop software which coordinates your freezing system with other equipment and production processes. As a result, the freezing of your products fits seamlessly into the overall operation. It is also possible to integrate other processes such as crate inverters, conveyor belts and feeder machines. Without changing or replacing existing software, you can control your entire freezing line at the touch of a button.

A single point of contact

You benefit from greater efficiency and maximum return from the freezing process because the cold store, freezing lines and peripherals are precisely coordinated by an intelligent control system. And if there is ever a malfunction in any of the components, you have a single point of contact for the entire system.

Ask about your savings potential

To test the effect of the freezing process on your product, we set up a test facility. We can also use simulation software to analyse the freezing process. Based on these models, we can calculate your theoretical energy consumption and carry out an economic study on the optimal freezing system for you.