Using existing energy streams

Are you taking advantage of the opportunities to use residual heat for other processes, to improve product quality or to increase hygiene levels in (high care) production areas? With our technology and expertise, you can take advantage of these opportunities. For example, you can use the residual heat from your cooling systems and production processes to heat water, to defrost and temper frozen products in a controlled manner, or to maintain temperature levels in the different production areas. By linking existing energy streams, you can reduce energy consumption and waste. If this does not cover your total heat requirement, you can for instance generate additional heat sustainably with a heat pump.

Reduce energy consumption? Use residual heat to meet your heating needs.

Request a free information brochureReduce moisture and condensation

Are you struggling to reduce moisture and condensation from cold stores to protect product quality? Ventilation with outside air reduces condensation in the (high-care) production areas, but this introduces bacterial risks that can influence quality and hygiene. Equans has therefore developed various systems that provide a grip on moisture regulation and condensation, without using outside air. This eliminates all hygiene risks and optimises product quality.

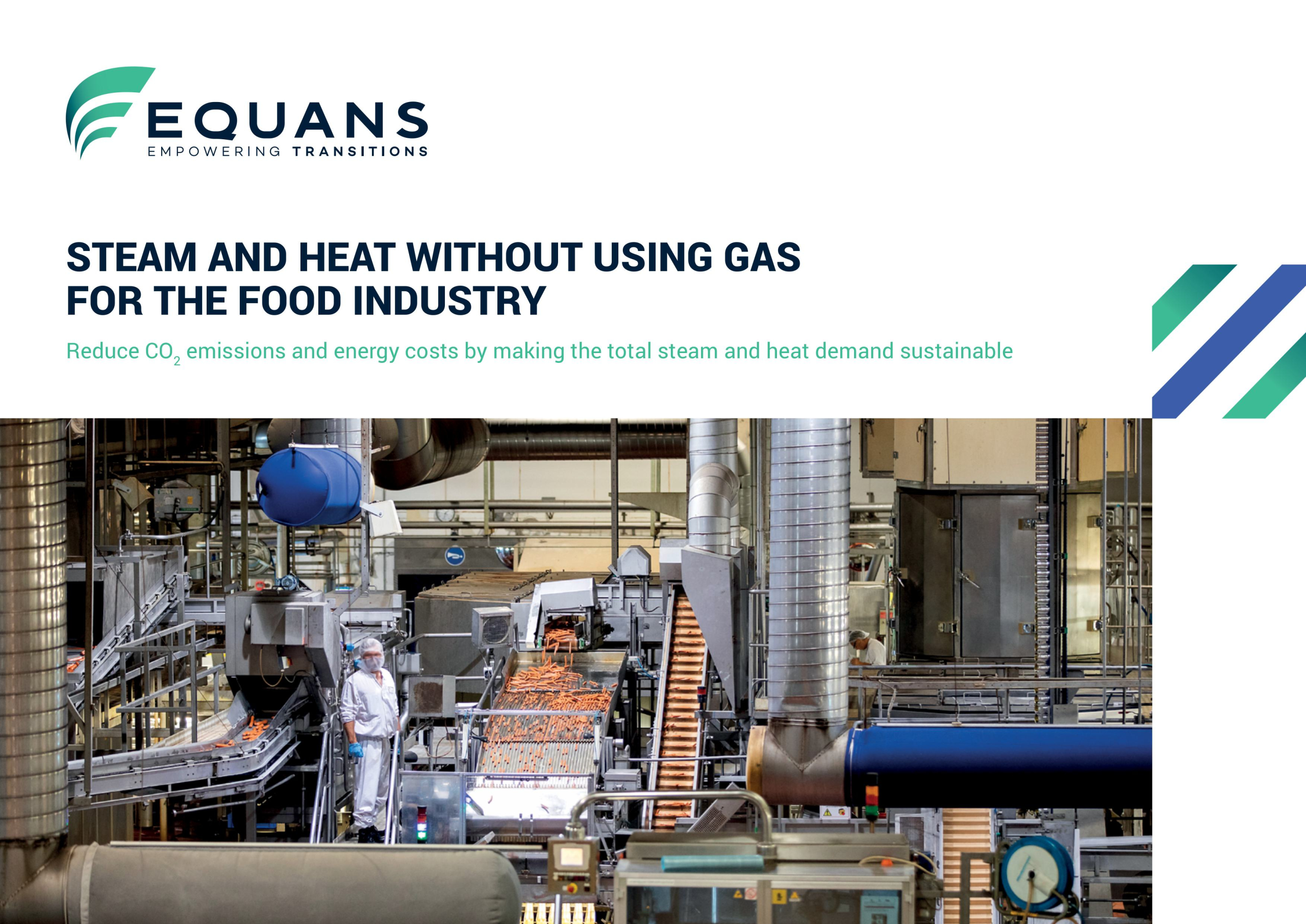

Need steam and heat for your production process? Check out our gas-free solutions. Reduce your CO2 emissions and energy costs!

Request a free information brochure

Secure your production process with natural refrigerants

Since 2022, it is not allowed to build new cooling installations with synthetic refrigerants that have a high GWP (Global Warming Potential). This is why we offer various suitable and safe applications for a future-proof alternative with natural refrigerants. By switching to natural refrigerants, you don’t only safeguard your own production process, but you can also benefit from interesting tax benefits.